From Chaos to Clarity: Master Your Stockroom with This Easy 5S Checklist (Copy)

Have you ever walked into your stockroom and felt that creeping dread? You know the feeling. Shelves overloaded with clutter, bins mislabeled or unlabeled entirely, and random supplies stacked wherever there’s room, quietly sabotaging your workflow. You’re not alone. A messy storage area isn’t just frustrating—it slows everything down. But here’s the good news: organizing your stockroom doesn’t have to be complicated. With the simple power of 5S, you can quickly turn a messy nightmare into a model of efficiency. Here’s exactly how you do it.

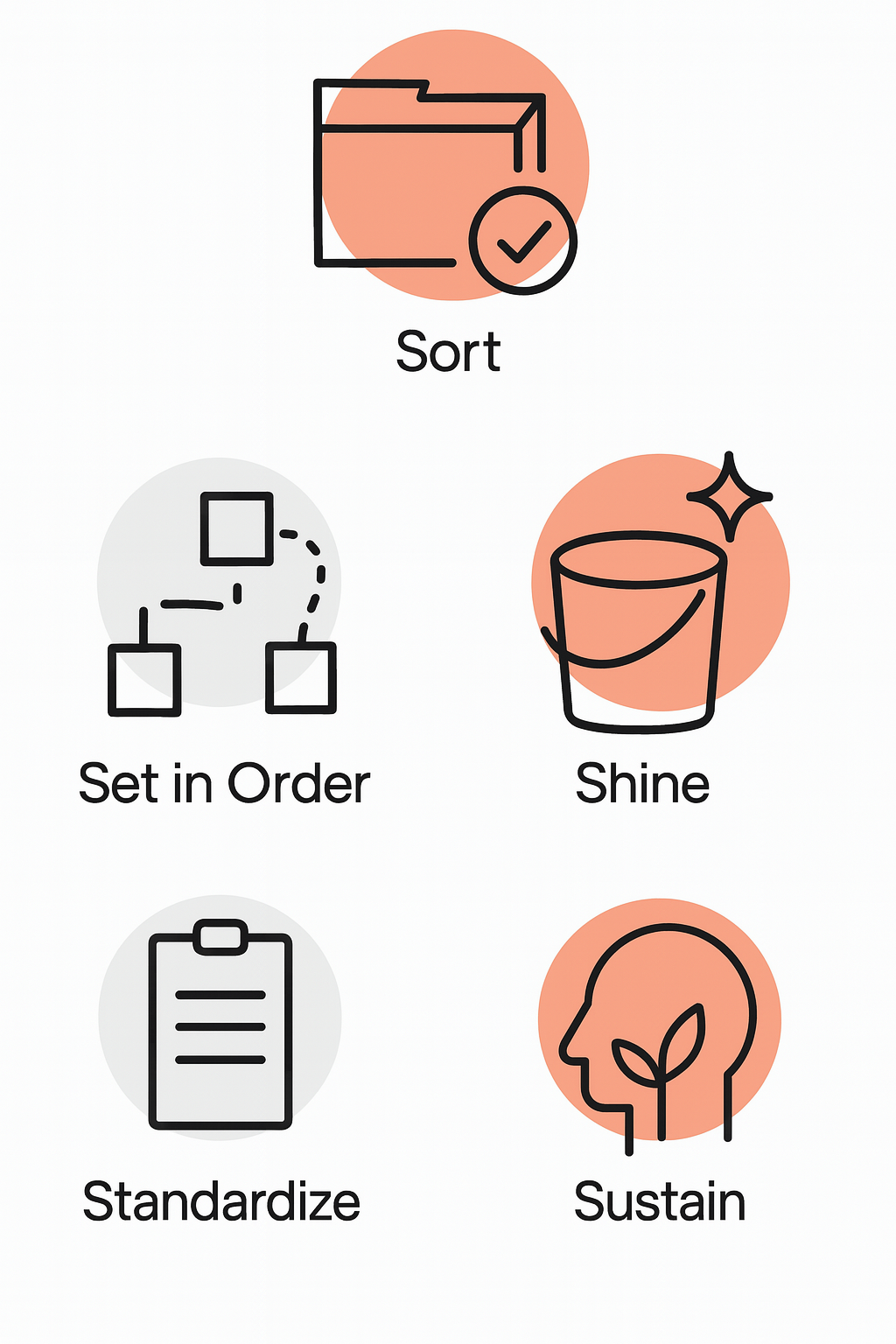

Quick 5S Audit: Get Your Stockroom in Shape

1. Sort (Seiri) – Clear the clutter.

✅ Remove obsolete or damaged items.

✅ Tag rarely used items for evaluation.

✅ Designate a "red tag" zone to temporarily hold questionable items.

Why it matters: Reduces clutter, frees up valuable space, and streamlines inventory management.

2. Set in Order (Seiton) – Everything has a place.

✅ Group similar items together by frequency of use.

✅ Label shelves and bins clearly, using visual identifiers (e.g., color codes, images, or part numbers).

✅ Arrange tools and materials based on flow (frequently accessed items closer to entry and exit points).

Why it matters: Minimizes searching, speeds up retrieval, and improves overall workflow efficiency.

3. Shine (Seiso) – Keep it clean and visible.

✅ Regularly sweep and dust shelves, bins, and storage areas.

✅ Schedule daily visual inspections to quickly spot misplaced items or maintenance issues.

✅ Implement a "clean-as-you-go" policy to keep the area ready for quick access.

Why it matters: Ensures visibility and accuracy, prevents downtime from dirty or faulty equipment, and promotes quick inventory audits.

4. Standardize (Seiketsu) – Set clear expectations.

✅ Create visual standards for stockroom organization (photos of ideal shelf setup, labels, and floor markings).

✅ Clearly post guidelines for stocking and restocking processes.

✅ Schedule regular 5S walk-through audits to maintain consistent standards.

Why it matters: Creates predictable processes, reduces variation, and maintains continuous organization and productivity.

5. Sustain (Shitsuke) – Make it stick.

✅ Provide brief, regular 5S training sessions or refreshers.

✅ Recognize and celebrate employees for maintaining 5S standards.

✅ Create an improvement board where team members can suggest ongoing 5S enhancements.

Why it matters: Builds a culture of continuous improvement, encourages ownership, and ensures long-term success of your organized system.